A pilot plant in the chemical/petrochemical industry is a small-scale simulation of manufacturing operations where results determine the most suitable process and the best equipment for scale up. A pilot plant reduces the technical and commercial risk associated with large process plants by providing valuable preliminary scientific data about reactions, material properties, process yields and more. It enables experiments that monitor all parameters, including pressure, temperature, flow rate, and reaction time. The objective is to continually improve the yield of the processes or develop new processes with higher yields.

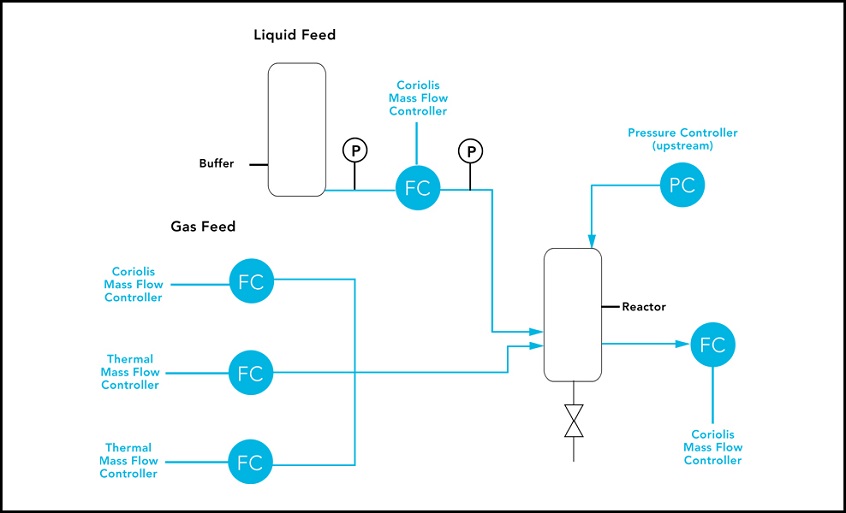

In a pilot plant, Brooks Instrument Coriolis and thermal mass flow controllers (MFCs) and pressure controllers monitor the gas or liquid flow rate and pressure input to a reactor and the flow output leaving the reactor, calculating the conversion between the input and output. The resulting data generates a mass balance equation for the process, providing critical data and direction on how to proceed.

Application Requirements

- Operation and accuracy at higher pressures (up to 300 Bar) and low flow rates (0.06 cc/min)

- Engineered to monitor mixed gases

- Long-term sensor stability (i.e. accuracy over time)

- Industry Compliance - Material Certification (2.1 or 3.1), NACE, calibration traceability, hazardous environment approvals

Process Solution

A Quantim® Coriolis mass flow controller measures a critical liquid feed(s) essential for the reaction. In addition, SLA thermal mass flow controllers measure less critical gas feeds to stabilize the reaction while maintaining long-term sensor stability during the process. Coriolis mass flow controllers may also used to measure other critical gas feeds.

Once the feeds reach the reactor, a reaction occurs. An upstream SLA5850 pressure controller, capable of controlling a range of gas pressures, ensures the pressure in the reactor is stable. Exiting the reactor, a Quantim® Coriolis mass flow meter measures the exhaust gases or liquids. This mass flow controller provides accurate data for mass-balance calculations used to assess the pilot plant results.

In addition, some pilot plants may be in an area that is considered hazardous. Brooks Instrument offers an array of certifications, approvals and options to ensure the equipment used in these critical applications meets applicable safety standards.